I was surprised to find that I could still log in here after a rather long absence. Anyway, as I am here, I may as well add some more to this old thread.

Re the Leyland Royal Tiger OPSU1 fitted with the AEC air-operated preselector gearbox, the conventional wisdom, as it were, is that the only batches so fitted were the 50 each for Sydney and Auckland. However, a while back I recently received information, including an old Leyland gearbox list that suggests that there may have been others.

This list showed the GB81, GB82 and GB90 designations used for Wilson gearboxes in the era at interest. The GB81 was described as an AEC unit, and appears to have been that fitted to the Sydney (and probably Auckland) Royal Tigers. GB82 was associated with LOPSU1, the left-hand drive chassis, and GB90 was shown as a special for Cuba. The last mentioned suggests that at least some of the large fleet of Cuban LOPSU1 Royal Tigers might have been fitted with Wilson gearboxes. And the existence of the GB82 entry suggests that there may have been other LOPSU1s so fitted. Of course, it is always possible that these covered variations mapped out but never built.

Also, the designation GB94 was used for the standard SCG RV16 Wilson gearbox, this being SCG’s initial version of the air-operated direct selection version. Evidently, Leyland made little use of this, moving very quickly to the RV28, which was its own-built, somewhat strengthened version.

I am guessing here, but the strengthening might have been required to handle the torque of the O.680 engine. It could be assumed that the internals of the RV16 were essentially the same as had been using for the preceding preselector version. It is known that they AEC preselector gearbox could handle the torque of the AEC 9.6 engine, but not that of the 11.3. When the latter was added as an option for the Regal IV, the use of the then-new Monocontrol gearbox was mandatory, whereas it was an option for the 9.6. One assumes that AEC’s Monocontrol had strengthening similar to that of the Leyland RV28. (The Regal IV struck me as a sad case anyway. Auckland had a handful (9.6/preselector), soon relegated to the relatively flat, slow-moving waterfront routes. It seemed to be a vehicle that would have been ideal for routes that were downhill both ways, with ambient temperatures not departing too much from about 10°C.)

One aspect of the Royal Tiger OPSU1/AEC preselector installation that I think has not previously been mentioned is that this variant had its engine mounted further forward than normal in order to accommodate that gearbox in island-mounted form.

I haven’t found a diagram that shows this altered layout. However, from the available diagrams of the standard Royal Tiger chassis with synchromesh transmission, one may deduce that for all wheelbase variants (OPSU3, OPSU1 and OPSU2), the engine was mounted such that its rear face was about 80 inches from the centreline of the rear axle.

Of those models, the long-wheelbase OPSU2 alone, late in its production run, was offered with the option of the then-new Pneumocyclic gearbox. In this case the engine was mounted further forward.

We may estimate that the rear face of the engine was placed about 102 inches ahead of the centreline of the rear axle, or 22 inches ahead of its normal position, to allow sufficient space for an island-mounted Pneumocyclic gearbox. The front of the gearbox was in the same position, relative to the rear axle, as the front of the manual gearbox on the standard model. There would appear to be some chance that the 22-inch number was derived from that of the preselector variant of the OPSU1, for which the work in accommodating the Wilson gearbox had already been done.

At least based upon very limited photographic evidence and remembered first-hand visual evidence from looking under an Auckland preselector Royal Tiger, having the engine 22 inches forward would seem to be about right. That would have put the rear face of the engine 108 inches behind the centreline of the front axle not much different to the short wheelbase OPSU3, where that distance was 107 inches.

It is difficult to know whether Leyland had planned it this way from the start, or whether the forward engine position with the Wilson gearbox was a post facto modification to meet customer requirements. However, in the late 1940s Leyland could have predicted that Sydney at least would be calling for the Wilson gearbox. It may also be noted that the Tiger Cub PSUC1, which was designed when the Pneumocyclic gearbox was in the planning stages, had different engine positions for the constant mesh and Pneumocyclic versions, with the engine further forward in the latter case.

As an aside, it may be noted that the Pneumocyclic was quite late in the Wilson gearbox sequence. SCG had developed the internally direct air-operated version of its epicyclic gearbox in the larger railway sizes during the second half of the 1930s. (New Zealand Railways was an early user.) But application of the same technique in the smallest size for road vehicle (and railcar) applications took quite a bit longer. Internal oil pressure operation had become available by the later 1940s, if not earlier. (The initial road vehicle version of this was the RV7, the gearbox that London Transport wanted but which AEC refused to build.) I have never seen an explanation as to why the air-operated version took so long to appear, but one possibility is that it took some design effort to get adequate band-holding pressure with the air cylinder size that could be fitted within the confines of the gearbox. Air leakage past the cylinder seals meant that the Pneumocyclic was harder on its fluid (in oxidation terms) than the preselector. That was likely one reason why Leyland developed its “Specification E” fluid (modified turbine oil).

Back to the Royal Tiger, this model was followed by the Royal Tiger Worldmaster, which had the island-mounted Pneumocyclic gearbox as standard. The same engine and gearbox positioning relative to the rear axle was adopted for all wheelbase variants, RT3 (16’3”), ERT1 (18’0”) and ERT2 (20’0”). Thus it would have been relatively easy for Leyland to provide the 17’6” wheelbase special version of the ERT1 for Sydney (and presumptively for Brisbane).

The uniformity of the engine and gearbox placement of Worldmaster was not replicated with the Leopard family, though.

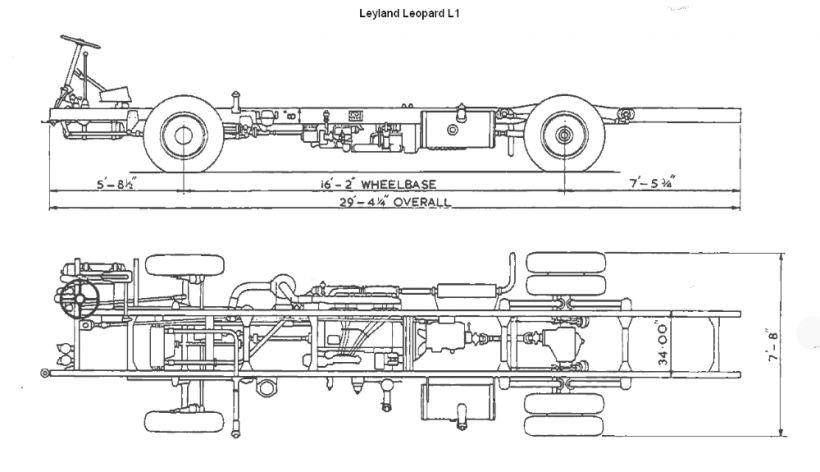

The original Leopard L (16’2” wheelbase) of 1959 was more-or-less a Tiger Cub with the O.600 engine, and sprung for 11 tons gvw. My best estimate is that the rear face of the engine was about 81 inches ahead of the rear axle. Whilst that was sufficient for a close-coupled synchromesh gearbox, it would have been insufficient for an island-mounted Pneumocyclic gearbox. The Pneumocyclic was never offered as an option on the L, nor as far as I know was it ever a special fitting. At the time, Leyland appeared to prefer the island-mounting for the Pneumocyclic, except where close-coupling was unavoidable, as on the Lion PSR1.

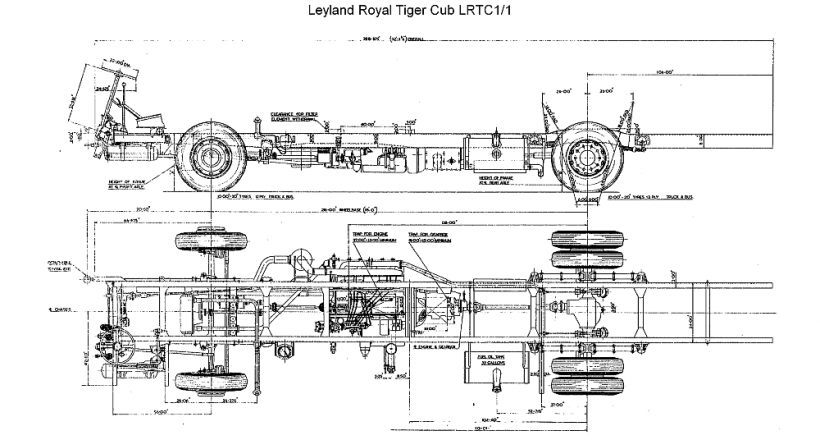

Next in the Leopard family was the Royal Tiger Cub RTC1 in 1960. This was essentially the L stretched to 18’0” wheelbase for a 33 ft nominal body, with 10-stud wheels and sprung for 13 tons gvw. It retained the same relatively short front overhang of the L. The engine appears to have been mounted in the same position relative to the front axle as on the L, so the “stretch” was all behind the engine. The chassis diagram shows the rear face of the engine to have been 102.6 inches ahead of the rear axle centreline, leaving enough room for the optional island-mounted Pneumocyclic gearbox.

Significant change came with the Leopard PSU3 in 1961, designed to meet the then-new British C&U regulations for 36 ft buses, but also destined to be a significant export model. The wheelbase went to 18’6” (about as long as would still meet the UK turning circle requirements) and the front overhang was extended quite a bit. Chassis changes included deletion of the slight hump over the rear axle, and moving the engine sideways slightly to put the crankshaft on the chassis centreline, and not slightly offset to the right as had been the case for the Tiger Cub, Leopard L and Royal Tiger Cub RTC1. The engine was about six inches further forward, relative to the front axle, than it had been on the L and RTC1. This meant that the rear face of the engine was something like 115 inches ahead of the rear axle, leaving more than enough room for an island-mounted Pneumocyclic gearbox. Design gvw remained at 13 tons, although UK domestic market models were sprung for 11¼ tons.

The next step in 1964 was twofold, development of the 17’6” wheelbase version of PSU3 for Brisbane, and of the 16’2” wheelbase PSU4 as the replacement for the L. Originally the latter was described as a “short PSU3”, developed at the request of CIE (Ireland) who wanted a the Pneumocyclic gearbox and a short companion to its regular PSU3 fleet.

The PSU3’s 115 inch spacing between the rear face of the engine and the rear axle would have allowed the subtraction of one foot from the wheelbase behind the gearbox without running out of room for the latter’s island mounting. I imagine that this is what was done for the Brisbane 17’6” wheelbase chassis, although I do not know for sure. However, the 1966-67 Wellington PSU3s, also of 17’6” wheelbase were allegedly based upon the Brisbane chassis, and these did have island-mounted gearboxes. My recollection of looking underneath one way back when was that the tailshaft was quite short.

But there would not have been enough room to subtract 22 inches from the wheelbase behind the gearbox for the “short PSU3” (PSU4). Thus of necessity, that was fitted with a close-coupled Pneumocyclic gearbox. By then, Leyland was using the close-coupled type in the Panther and Panther Cub, so may have been less averse to it than previously. Assumed is that the engine position relative to the front axle stayed the same as for the standard PSU3.

That brings us to the Sydney PSU3 Leopard fleet. The first tranche of 232 had close-coupled gearboxes, described as being PSU4-style. The question is, was the engine moved backwards to meet the gearbox, was the gearbox moved forward to meet the engine, or were both moved to “meet in the middle” as it were. Applying Occam’s Razor suggests that the simplest solution was that the engine and gearbox were in the PSU4 position relative to the rear axle, and that the initial Sydney PSU3 was basically a PSU4 with the wheelbase extended by 1’4” ahead of the engine. The balance of the Sydney Fleet had the island-mounted gearbox as far as I know.

The Perth PSU3, with the standard 18’6” wheelbase, was known to have had its engine moved backwards relative to the standard position for better weight balance. Again application of Occam’s Razor suggests that the PSU4 engine/gearbox assembly was used, in its customary position relative to the rear axle. That would have made the chassis effectively a PSU4 with a 2’4” wheelbase extension ahead of the engine. But it might well have been otherwise.

Cheers,